In the rapidly evolving healthcare sector, precision and

innovation in Medical Device Design and Development are essential for

delivering safe, effective solutions that improve patient care. Raydeyo

Technical Solutions LLC offers expert services across the entire development

lifecycle, including medical device prototyping, simulation, machine design,

and industrial drafting services, providing a comprehensive pathway from

concept to market.

Medical device design demands specialized knowledge of

regulatory standards, biocompatible materials, and ergonomic functionality. Our

experienced engineers work closely with clients to develop innovative designs

that meet medical, technical, and compliance requirements. We focus on creating

user-friendly devices with optimal performance, reliability, and safety.

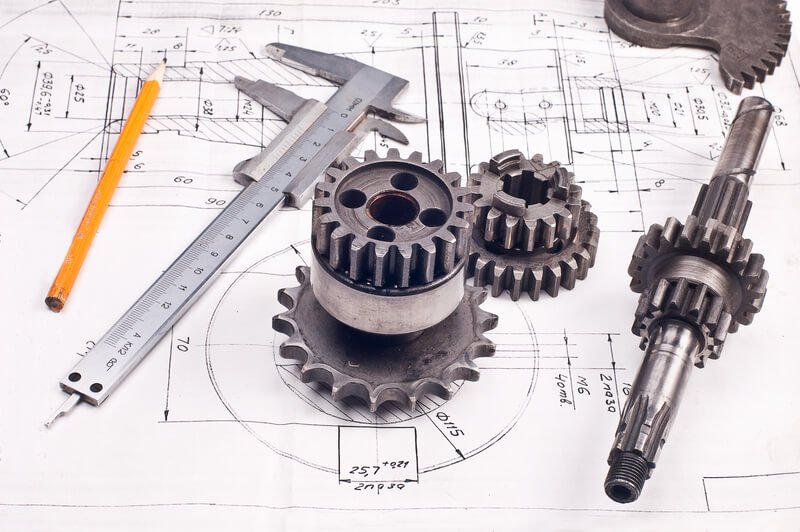

Machine design and industrial drafting services are integral

to translating medical device concepts into manufacturable products. Our

skilled drafting engineers produce detailed 2D and 3D CAD models, assembly

drawings, and documentation in line with industry standards. Precise drafting

ensures manufacturers can accurately fabricate components and helps streamline

regulatory submissions, reducing time-to-market and development costs.

Medical device prototyping is a critical phase where

concepts become tangible units used for testing and validation. Raydeyo

Technical Solutions LLC utilizes advanced prototyping techniques, including

rapid 3D printing and CNC machining, to produce highly detailed and functional

models. These prototypes enable early detection of design issues, usability

testing, and iterative improvements, ensuring the device’s durability and

performance meet clinical expectations.

Simulation and testing play a vital role in verifying the

safety and efficacy of medical devices. Our engineers use cutting-edge software

to simulate mechanical behavior, fluid dynamics, and material responses,

allowing us to predict real-world device performance without costly physical

trials alone. Simulation helps identify stress points, wear, and potential

failure modes, guiding design refinements to enhance device longevity and

compliance with regulatory standards.

Beyond virtual simulations, we conduct rigorous physical

testing tailored to industry protocols, including mechanical endurance, impact

resistance, and biocompatibility. Combining simulation and testing accelerates

development cycles, mitigates risks, and ensures devices conform to FDA or CE

standards, which are crucial for market approval.

Raydeyo Technical Solutions LLC’s integrated approach

empowers medical device companies to innovate confidently. From initial machine

design and drafting services to prototyping, simulation, and testing, we

provide comprehensive support that bridges engineering expertise with

regulatory demands and manufacturing feasibility.

Our commitment to quality, precision, and collaboration

enables efficient product development, reduced costs, and faster market entry

for clients in medical technology sectors. Whether designing complex diagnostic

tools, wearable devices, or surgical instruments, Raydeyo delivers tailored

solutions that meet the unique challenges of medical device engineering.

In summary, combining expert Medical Device Design and

Development with precise Machine Design and Industrial Drafting, along with

thorough Medical Device Prototyping and Simulation and Testing services,

positions Raydeyo Technical Solutions LLC as a trusted partner in healthcare

innovation. Partner with us to transform medical device ideas into reliable,

compliant, and market-ready products.